Integrated Nanofabrication and Cleanroom Facility (INCF)

Lehigh's Integrated Nanofabrication and Cleanroom Facility (INCF) consists of the III-V and Silicon-based nanofabrication cleanrooms, consolidated into a single facility with expansion in both space and equipment. The cleanroom facility supports research and developments in microfabrication techniques, and device fabrications.

Patterning

The INCF houses a Class 100 photolithography room for all of their coating and patterning. Utilizing the programmable Solitec spinner, researchers coat various polymers and resists with up to 5 separate spin speeds and times. The Karl Suss MA 6/BA6 aligner is capable of both front and backside alignment and can achieve 2 um resolution on samples ranging from small pieces up to 3 inches.

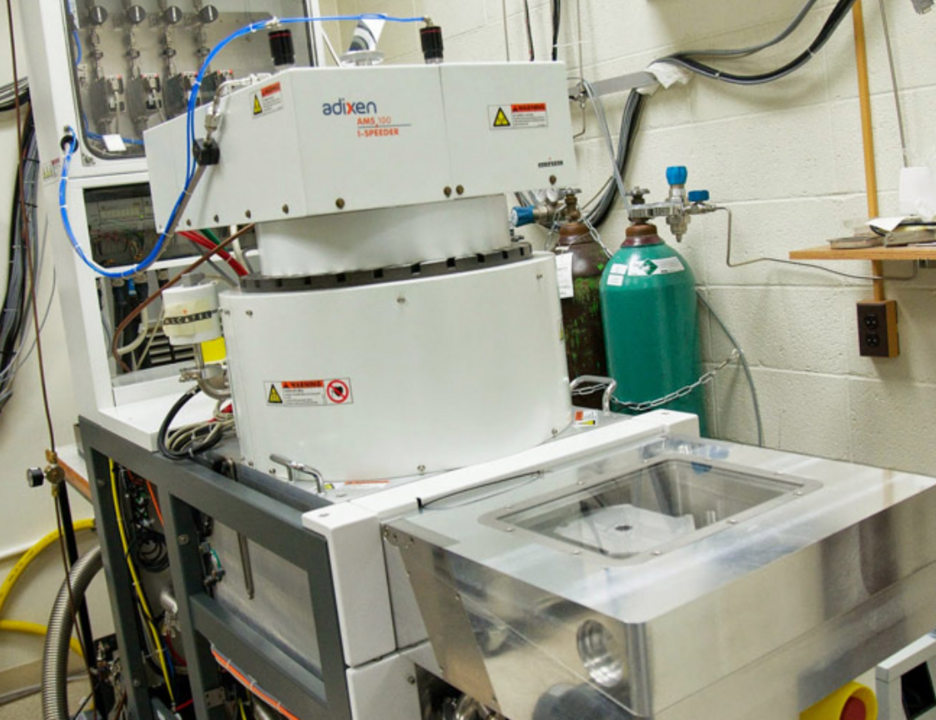

Etching

The INCF cleanroom offers flexible Plasma and Wet etch technology on a wide range of applications. Research processing of III-V, Silicon Bosch and Dielectric films is achieved with our RIE’s, DRIE and Wet Etch Chemistry etching. Piece processing and samples up to 6 inches can be processed.

Deposition and sputtering

High quality deposition and thin film coatings are provided by a select equipment set with proven success across a wide range of technologies. The cleanroom facility offers both E – Beam and Sputtering applications along with Plasma Enhanced dielectric depositions.

Packaging

INCF packaging facilities support a variety of technologies and equipment to meet the needs of our researchers. Precise sample preparation of a wide range of materials is possible utilizing our capabilities in Polishing, Sectioning and Wire Bonding.